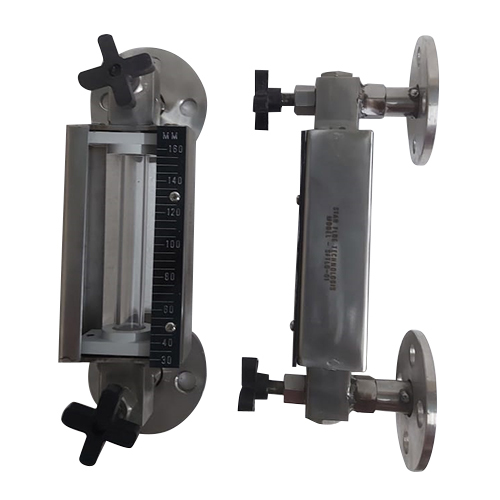

Tubular Level Gauge

Product Details:

- Usage Industrial

- Color Gray

- Size Different Available

- Material Metal

- Grade Industrial

- Click to View more

Tubular Level Gauge Price And Quantity

- 5500 INR/Unit

- 2 Unit

Tubular Level Gauge Product Specifications

- Gray

- Different Available

- Metal

- Industrial

- Industrial

Tubular Level Gauge Trade Information

- 50 Unit Per Month

- 5 Days

- All India

Product Description

A form of level measurement instrument used to visually monitor the level of liquid in a tank or vessel is a tube level gauge, sometimes referred to as a sight glass level gauge or a liquid level indicator. It is made up of a clear tube or piece of glass that is fixed vertically on the tank's side and allows for clear visual inspection of the liquid level within.

The main elements and characteristics of a tubular level gauge are as follows:

1. Transparent Tube: A transparent tube constructed of materials like glass, acrylic, or polycarbonate serves as the major structural element of the tubular level gauge. In order to allow the liquid inside to fill the tube to the same level as the liquid in the tank, the tube is positioned vertically on the tank or vessel.

2. Graduations or a level scale may be written on the tube's side to serve as measuring points or references for the liquid's level. Ordinarily, the scale is calibrated using measurements like inches, centimetres, or a percentage of tank capacity.

3. Process Connections: To accommodate diverse tank configurations, tubular level gauges are offered with several types of process connections. These connectors, which can be welded, threaded, or flanged, make it simple to install and integrate them into the tank or vessel.

4. Liquid Chamber: The transparent tube has liquid chambers or headers at the top and bottom that serve as reservoirs and maintain a steady flow of liquid into the tube. Additionally, these chambers act as a barrier to keep the liquid inside the gauge and stop leaks.

5. In order to allow for isolation, maintenance, or replacement of the gauge without draining the tank or stopping the process, tubular level gauges may have valves or isolation mechanisms at the top and bottom of the gauge.

6. Tubular level gauges can be fitted with protective shields, such as metal or plastic guards, to shield the clear tube from potential damage or breaking. In order to improve vision in low light or reading accuracy, additional accessories like illuminating devices or magnifying lenses may be added.

Numerous industries, including oil and gas, chemical processing, pharmaceuticals, water treatment, and storage tanks, frequently employ tubular level gauges. They offer an easy, affordable, and dependable way to visually monitor liquid levels without the use of complicated electronics or power sources.

Consider factors like material compatibility with the process fluid, temperature and pressure restrictions, visibility requirements, scale readability, installation considerations, and any unique requirements related to the application or industry when choosing a tubular level gauge. To select the best tubular level gauge for your unique needs, it is important to speak with level gauge suppliers or manufacturers.

|

STAR FLOW TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry